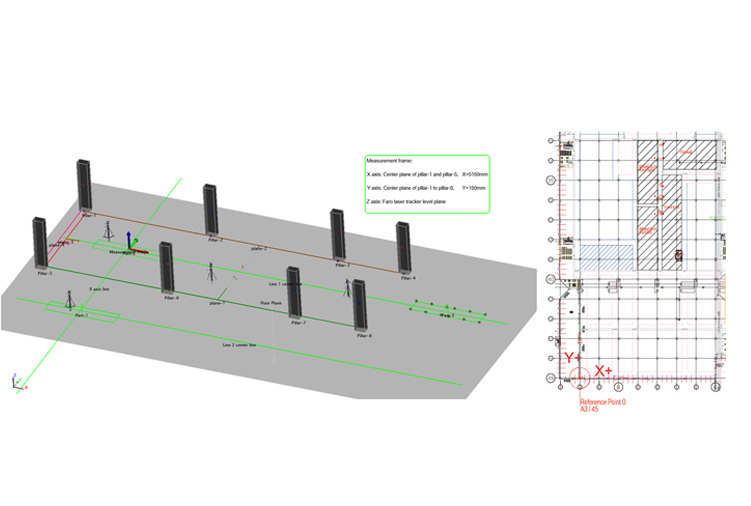

Tooling installation and positioning

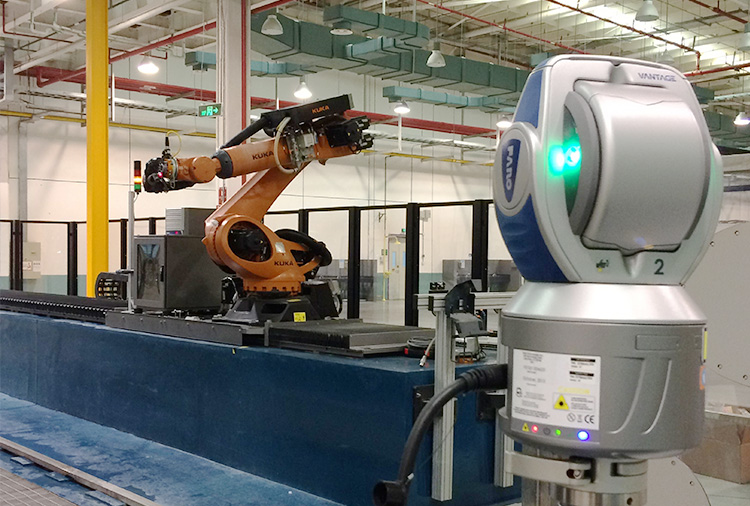

The construction of a production line is a process following certain principles which are subject to objects and space in order to achieve specific design objectives. For enterprises, all of these machines and facilities including plants, main/auxiliary engines, auxiliary equipment, special equipment, special toolings, instruments, meters, weighing apparatus, containers, transportation facilities, and mechanics, power supply, illuminating systems, steam supply, water supply, air conditioning, pipelines, lifting, transportation, etc. require systematic and accurate positioning.

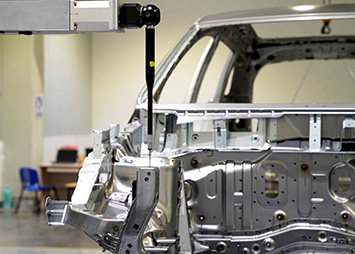

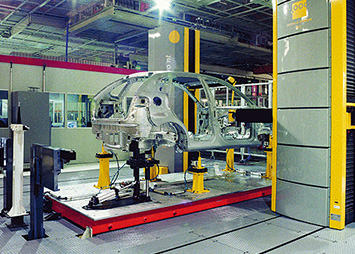

After its transformation from a manufacturing country to a world power, China seeks always higher automation capability and quality products. Its large-scale production lines play a key role in industrial production. And nowadays intellectualized market and industries make those large-scale production lines tend to be more accurate, professional, intelligent, systematic and numerical.